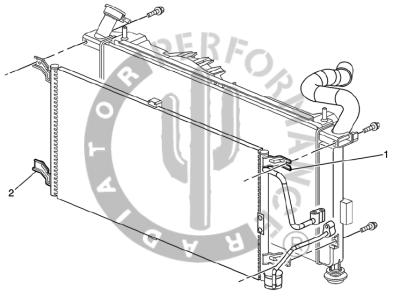

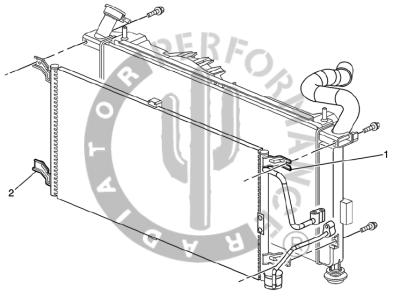

Picture 1: Condenser mounting changes

The new Performance Radiator brand heat exchanger you are installing may be different slightly different than the one you are removing from your vehicle. This sheet will identify those differences, but rest assured that these changes are intentional and are intended to increase the service-life and performance of your new Performance Radiator Brand heat exchanger.

Previously the OE manufacturer found that the condenser’s original mounting design/configuration was the reason for many premature failures. This mounting style constricted the condenser and resisted the expansion and contraction of the condenser caused by it warming up and cooling down (thermal cycling). This resulted in extreme stress being applied to the tube-to-manifold joint, which caused the joint to leak (stress fracture). Imagine bending a paperclip back and forth repeatedly, eventually the paperclip breaks. This is what happened to the tubes at the tube-to-manifold joint.

The OE manufacturer resolved this problem by adding a slot to upper right mount (#1 in the picture below) and removing a bolt from the bottom left mount (#2 in the picture below). To help ensure that our part would not fail prematurely for the same reasons, we followed the OE manufacturer and made the same changes.